Industrial Mobile Robot Glossary for Warehousing and Logistics

By AMT Senior Application Engineer Marcus Chisholm and Innovation Manager Jason Markesino

Download our comprehensive IMR glossary, a valuable resource which covers a wide range of essential terms and acronyms related to mobile robots.

Understanding Industrial Mobile Robots within Warehousing and Logistics

In an industrial setting, the majority of robots are stationary, limited by their predefined reach and weight capacity to handle parts within their designated area. This is where mobile robots come in to fill the gaps for additional needs within warehousing and logistics. As the name implies, mobile robots are capable of moving around a defined workspace and are often used for material handling tasks in the warehousing and logistics industries. Mobile robots not only elevate industrial automation but can also save on labor costs and significantly boost throughput.

In an industrial setting, the majority of robots are stationary, limited by their predefined reach and weight capacity to handle parts within their designated area. This is where mobile robots come in to fill the gaps for additional needs within warehousing and logistics. As the name implies, mobile robots are capable of moving around a defined workspace and are often used for material handling tasks in the warehousing and logistics industries. Mobile robots not only elevate industrial automation but can also save on labor costs and significantly boost throughput.

While the conventional method for moving materials across the factory floor has relied on conveyor systems, mobile robots provide a conveyor-free solution, offering the flexibility to cover the entire factory floor with their extensive range of motion.

To reap these benefits, all types of industrial mobile robots (IMRs), including automatic guided vehicles (AGVs) and autonomous mobile robots (AMRs), are becoming more prevalent in the modern facility. As special territory of robotic solutions, IMRs have a unique language, terminology, and set of acronyms.

Download our seven-page glossary of IMR terms to help you understand this new technology.

Learn the Language of Industrial Mobile Robots

The IMR Glossary covers:

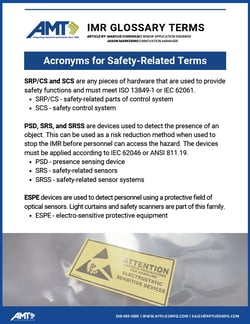

- Acronyms for safety-related terms

- Cybersecurity

- Electromagnetic compatibility (EMC) and electrostatic discharge (ESD)

- Industrial mobile robot fleet (IMRF) and fleet manager

- Operating environments

- Personnel

- Space-related terms

- Types of stations

- Definition of zones

Mobile robots in warehouse and logistic settings offer increased flexibility and efficiency, allowing them to complete material handling tasks throughout the factory floor, bypassing traditional conveyor systems. These robots, including AGVs and AMRs, are on the rise and have their own unique terminology, making a glossary of IMR terms a valuable resource for those looking to understand this technology.

Download our IMR glossary, which covers essential aspects such as safety-related acronyms, cybersecurity, operating environments, and more.